future engineers

today I will continue explaining the fifth item from basic elevator components which is Control system as follows.

You can review the following prevouis topics for more information and good following.

Fifth: Elevator Control System

Elevator Control System is the system responsible for coordinating all aspects of elevator service such as travel, speed, and accelerating, decelerating, door opening speed and delay, leveling and hall lantern signals.

It accepts inputs (e.g. button signals) and produces outputs (elevator cars moving, doors opening, etc.).

Aims of the control system

The main aims of the elevator control system are:

Types of elevator control systems:

2- Selective collective operation:

3- Group automatic operation:

Note: the Traffic management systems which combine visual monitoring, interactive command control, and traffic analysis to ensure that the elevators are running properly will be discussed in another course for planning and design of elevators traffic management systems.

Elevator control system components:

The elevator as a control system has a number of components. These can basically be divided into the following:

1- Inputs, which include:

A- Sensors.

B- Buttons.

C- Key controls.

D- System controls.

A- Sensors

A.1 Magnetic and/or photo electric:

These pick up signals regarding the location of the car. This sensor is usually placed on the car itself and reads the position by counting the number of holes in the guide rail as they pass by in the photo-electric sensor or in the case of the magnetic sensor, the number of magnetic pulses.

A.2 Infrared:

This is used to detect people entering or leaving the elevator.

A.3 Weight sensor (OverLoad Device):

This is placed on the car to warn the control system if the design load is exceeded.

A.4 PVT (primary velocity transducer):

Velocity of the drive sheave is sensed with this encoder.

B- Buttons

B.1 Hall Buttons:

These buttons are on a button panel on the outside of the elevator shafts and are used by potential passengers to call an elevator cab to the floor that the pressed summon button is located on. There are two Hall buttons on each floor – one for up, another for down, except on the top floor where there is only down and on the bottom floor where there is only up. The controller interacts with these buttons by receiving press and release signals indicating the requested direction and floor number. It also sends light on/off signals to indicate the status of the buttons.

B.2 Floor Request Buttons:

This particular elevator controller will be controlling elevator cabs that are in a building with 6 floors. Consequently, each cab has 6 floor request buttons labeled 1 through 6 that passengers can use to direct the elevator cabs to the floor that they would like to go to.

These buttons are located on a button panel on the interior of each elevator cab. The controller interacts with these buttons by receiving pressed signals indicating the desired floor number and elevator cab which they were pressed from. It also sends light on/off signals to indicate the status of the buttons.

B.3 Open Door Button:

This button is on the interior button panel of each cab. A passenger can press this button to open the elevator doors or keep pressing it to keep them open, but only when the elevator cab is stopped at a floor. Some elevator systems also have a close door button, but this one does not. The controller interacts with this button by receiving a signal when it is pressed and when it is released. Both of these signals include the cab from which they came from.

B.4 Emergency Stop Button:

This button is on the interior button panel of each cab. A passenger can press this button to stop the elevator no matter where it is in a shaft. The controller interacts with this button by receiving a signal from it that indicates that it was pressed, as well as the cab that it came from.

B.5 Emergency Bell Button:

This button is on the interior button panel of each cab. A passenger can press this button to sound a bell to alert people outside of the elevator shaft that someone is trapped inside the elevator cab in case of a malfunction. The controller interacts with this button by receiving a signal from it that indicates that it was pressed.

B.6 Registration panel

In destination control systems, the conventional hall call buttons (Up and Down arrows) located at the elevator lobby are replaced by the registration devices. Passengers register their destination floor through these registration devices at the lobby instead of in the elevator. The registration device will display the elevator that has been assigned for transporting the passenger. As the passenger has already registered the desired destination floor, there is no need to input the destination floor in the elevator.

C- Key Controls

Key controls may only be activated by the proper keys, and their use is thus restricted to repair people, elevator operators or firemen. It is used in place of or in conjunction with a pushbutton to restrict access to a floor. Keypads and card readers are also available. Examples for these keys are as follows:

D- System Controls

System controls are used to turn the elevator system on or off, system controls are only accessible from an elevator control room. They would typically be used quite infrequently – perhaps the system would be turned on early in the morning and turned off late at night, or turned off at the start of holidays and turned on once the next term begins.

2- Outputs, which include:

A- Actuators.

B- Bells.

C- Displays.

A- Actuators

A.1 Door Opening Device:

On top of each elevator cab is a door opening device. This device opens the inner door of the elevator cab and the outer door of the elevator shaft simultaneously at each floor. The controller interacts with the door opening device by sending signals to open or close the doors and by receiving signals when the doors have been completely opened or closed. The signals that the controller receives also indicate which cab they are coming from.

A.2 Electric motor:

The elevator motor is responsible for moving an elevator cab up and down between floors. As this elevator system uses a roped mechanism, the elevator engine is connected to a sheave which the ropes are looped around. The controller interacts with the elevator engine by sending it a signal that specifies at which speed and in what direction the engine should be going in. A stop signal is simply constructed by setting the speed parameter of the signal to zero.

A.3 Brakes:

There a few brake systems in a typical elevator system. These include the electromagnetic and mechanical brakes. The electromagenetic brakes activate automatically if there is a sudden loss of power or when the car is stationary. The mechanical brakes at the sheave itself also stop the car from moving when the car is inactive.

B- Bells

B.1 Emergency Bell:

Somewhere in the elevator system is an emergency bell that is used to alert people outside of the elevator system that someone is trapped inside an elevator cab. The controller interacts with the emergency bell by sending it a signal to ring.

B.2 Load Bell:

Each cab has a load bell that is used to alert the passengers inside the cab that there is too much weight in it to operate it safely. The controller interacts with the load bell be sending it a signal to ring.

C- Displays

C.1 Car Position Display:

The interior of each elevator cab has a display that indicates to its passengers which floor the elevator cab is currently on. Some elevator systems have this floor number display on every floor outside of the elevator doors, but this system does not. The controller interacts with this display by sending a signal that tells it which floor number to display. Can be either analog (individual indicators for each floor) or digital ( a dot matrix or segmented LED that changes to indicate the floor level)

C.2 Direction Display:

The interior of each elevator cab has a display that indicates the current direction of an elevator cab; it is either up or down. The controller interacts with this display by sending it a signal that tells it which direction to display.

3- Controller

The controller is a device which manages the visual monitoring, interactive command control and traffic analysis system to ensure the elevators are functioning efficiently.

The primary function of the elevator controller

The primary function of the elevator controller is essentially to receive and process a variety of signals from several different components of a whole elevator system. It is able to send signals in response to the ones it receives in order to operate all of the other components in the system. This exchange of signals is how the elevator controller is able to keep the elevators running smoothly on a day-to-day basis.

Here are a few of the following ways the controller interacts with the other components of the elevator system:

Types of elevator controllers:

There are 3 primary types of controller technology used to process the logic of the controller as follows:

1- Relay based controller (electromechanical switching)

A relay is a very dependable device consisting of an electromagnet that opens and closes contacts, routing the logic to various circuits. A simple elevator with a few stops and manual door operation can be served well by a relay controller. Relays can also be used for more complex elevators, and in fact were until the 1980's. However, the number of relays required can make it difficult to troubleshoot should there ever be a problem.

The following applications may be recommended as suitable for controllers using electromagnetic relay technology:

2- Solid-State Logic Technology

It includes both discreet transistors circuits and integrated circuit boards. It gives improved reliability, lower power consumption and easy fault diagnosis than electromagnetic relay technology.

The following applications are recommended as suitable for controllers using solid-state logic technology:

3- PLC controller (computer based technology)

The advent of personal computers has made microprocessor technology affordable for many other fields. Elevator Concepts utilizes a special type of industrial computer called a Programmable Logic Controller PLC to control the logic of more complex jobs. They are very dependable, compact, and simple to troubleshoot.

Computer based controllers are suitable for the following:

Elevator Control System Sequence Diagrams

The elevator control system may be viewed either from the point of view of an individual user or as a system being acted on by many users and the following images show these different point of views.

1- From the point of view of an individual user:

2- From the point of view as a system being acted on by many users:

Elevator Control System

In the topic " Basic Elevator Components - Part One" , I indicate that the basic elevator components are as follows:

I explained the elevator car components in this prevouis topic, and I explained the Hoistway and its components in the topic "Basic Elevator Components - Part Two". also, I explained the Machine/drive system in the topic" Elevator Machine and Drive System " and I explained the elevator safety system in the topic " Elevator Safety System ".today I will continue explaining the fifth item from basic elevator components which is Control system as follows.

You can review the following prevouis topics for more information and good following.

Fifth: Elevator Control System

Elevator Control System is the system responsible for coordinating all aspects of elevator service such as travel, speed, and accelerating, decelerating, door opening speed and delay, leveling and hall lantern signals.

It accepts inputs (e.g. button signals) and produces outputs (elevator cars moving, doors opening, etc.).

|

| Simple Elevator Control System Inputs and Outputs |

Aims of the control system

The main aims of the elevator control system are:

- To bring the lift car to the correct floor.

- To minimize travel time.

- To maximize passenger comfort by providing a smooth ride.

- To accelerate, decelerate and travel within safe speed limits.

Types of elevator control systems:

there are 3 main types for elevator control systems as follows:

1- Single Automatic operation:

1- Single Automatic operation:

- First automated system w/o single call button on each floor and single button for each floor inside car.

- Called if no one is using it.

- Passenger has exclusive use of the car until rip is complete.

2- Selective collective operation:

- Most common, remembers and answers calls in one direction then reverses. When trip complete, programmed to return to a home landing.

3- Group automatic operation:

- For large buildings with many elevators which are controlled with programmable microprocessors to respond.

Note: the Traffic management systems which combine visual monitoring, interactive command control, and traffic analysis to ensure that the elevators are running properly will be discussed in another course for planning and design of elevators traffic management systems.

Elevator control system components:

The elevator as a control system has a number of components. These can basically be divided into the following:

- Inputs.

- Outputs.

- Controllers.

1- Inputs, which include:

A- Sensors.

B- Buttons.

C- Key controls.

D- System controls.

A- Sensors

A.1 Magnetic and/or photo electric:

|

| photo electric Car Position Sensor |

These pick up signals regarding the location of the car. This sensor is usually placed on the car itself and reads the position by counting the number of holes in the guide rail as they pass by in the photo-electric sensor or in the case of the magnetic sensor, the number of magnetic pulses.

A.2 Infrared:

|

| Infrared Sensor |

This is used to detect people entering or leaving the elevator.

A.3 Weight sensor (OverLoad Device):

|

| Weight Sensor |

This is placed on the car to warn the control system if the design load is exceeded.

A.4 PVT (primary velocity transducer):

Velocity of the drive sheave is sensed with this encoder.

B- Buttons

B.1 Hall Buttons:

|

| Hall Buttons |

These buttons are on a button panel on the outside of the elevator shafts and are used by potential passengers to call an elevator cab to the floor that the pressed summon button is located on. There are two Hall buttons on each floor – one for up, another for down, except on the top floor where there is only down and on the bottom floor where there is only up. The controller interacts with these buttons by receiving press and release signals indicating the requested direction and floor number. It also sends light on/off signals to indicate the status of the buttons.

B.2 Floor Request Buttons:

|

| Floor Request Buttons |

This particular elevator controller will be controlling elevator cabs that are in a building with 6 floors. Consequently, each cab has 6 floor request buttons labeled 1 through 6 that passengers can use to direct the elevator cabs to the floor that they would like to go to.

These buttons are located on a button panel on the interior of each elevator cab. The controller interacts with these buttons by receiving pressed signals indicating the desired floor number and elevator cab which they were pressed from. It also sends light on/off signals to indicate the status of the buttons.

B.3 Open Door Button:

This button is on the interior button panel of each cab. A passenger can press this button to open the elevator doors or keep pressing it to keep them open, but only when the elevator cab is stopped at a floor. Some elevator systems also have a close door button, but this one does not. The controller interacts with this button by receiving a signal when it is pressed and when it is released. Both of these signals include the cab from which they came from.

B.4 Emergency Stop Button:

This button is on the interior button panel of each cab. A passenger can press this button to stop the elevator no matter where it is in a shaft. The controller interacts with this button by receiving a signal from it that indicates that it was pressed, as well as the cab that it came from.

B.5 Emergency Bell Button:

This button is on the interior button panel of each cab. A passenger can press this button to sound a bell to alert people outside of the elevator shaft that someone is trapped inside the elevator cab in case of a malfunction. The controller interacts with this button by receiving a signal from it that indicates that it was pressed.

B.6 Registration panel

In destination control systems, the conventional hall call buttons (Up and Down arrows) located at the elevator lobby are replaced by the registration devices. Passengers register their destination floor through these registration devices at the lobby instead of in the elevator. The registration device will display the elevator that has been assigned for transporting the passenger. As the passenger has already registered the desired destination floor, there is no need to input the destination floor in the elevator.

C- Key Controls

|

| Fireman's service Switches |

Key controls may only be activated by the proper keys, and their use is thus restricted to repair people, elevator operators or firemen. It is used in place of or in conjunction with a pushbutton to restrict access to a floor. Keypads and card readers are also available. Examples for these keys are as follows:

- Fireman's service, phase II key switch.

- An inspector's switch, which places the elevator in inspection mode (this may be situated on top of the elevator).

- Manual up/down controls for elevator technicians, to be used in inspection mode, for example.

- An independent service/exclusive mode Switch (also known as "Car Preference"), which will prevent the car from answering to hall calls and only arrive at floors selected via the panel. The door should stay open while parked on a floor. This mode may be used for temporarily transporting goods. The controller interacts with the switch by receiving a signal from it when it has been toggled to either AUTO or HOLD mode. AUTO is for normal operation; HOLD is to keep the elevator cab from moving and its doors from opening or closing.

- Attendant service mode switch.

D- System Controls

System controls are used to turn the elevator system on or off, system controls are only accessible from an elevator control room. They would typically be used quite infrequently – perhaps the system would be turned on early in the morning and turned off late at night, or turned off at the start of holidays and turned on once the next term begins.

2- Outputs, which include:

A- Actuators.

B- Bells.

C- Displays.

A- Actuators

A.1 Door Opening Device:

|

| Door Opening Device |

On top of each elevator cab is a door opening device. This device opens the inner door of the elevator cab and the outer door of the elevator shaft simultaneously at each floor. The controller interacts with the door opening device by sending signals to open or close the doors and by receiving signals when the doors have been completely opened or closed. The signals that the controller receives also indicate which cab they are coming from.

A.2 Electric motor:

The elevator motor is responsible for moving an elevator cab up and down between floors. As this elevator system uses a roped mechanism, the elevator engine is connected to a sheave which the ropes are looped around. The controller interacts with the elevator engine by sending it a signal that specifies at which speed and in what direction the engine should be going in. A stop signal is simply constructed by setting the speed parameter of the signal to zero.

A.3 Brakes:

There a few brake systems in a typical elevator system. These include the electromagnetic and mechanical brakes. The electromagenetic brakes activate automatically if there is a sudden loss of power or when the car is stationary. The mechanical brakes at the sheave itself also stop the car from moving when the car is inactive.

B- Bells

B.1 Emergency Bell:

Somewhere in the elevator system is an emergency bell that is used to alert people outside of the elevator system that someone is trapped inside an elevator cab. The controller interacts with the emergency bell by sending it a signal to ring.

B.2 Load Bell:

Each cab has a load bell that is used to alert the passengers inside the cab that there is too much weight in it to operate it safely. The controller interacts with the load bell be sending it a signal to ring.

C- Displays

C.1 Car Position Display:

|

| Car Position Display |

The interior of each elevator cab has a display that indicates to its passengers which floor the elevator cab is currently on. Some elevator systems have this floor number display on every floor outside of the elevator doors, but this system does not. The controller interacts with this display by sending a signal that tells it which floor number to display. Can be either analog (individual indicators for each floor) or digital ( a dot matrix or segmented LED that changes to indicate the floor level)

C.2 Direction Display:

|

| Direction Display |

The interior of each elevator cab has a display that indicates the current direction of an elevator cab; it is either up or down. The controller interacts with this display by sending it a signal that tells it which direction to display.

3- Controller

The controller is a device which manages the visual monitoring, interactive command control and traffic analysis system to ensure the elevators are functioning efficiently.

The primary function of the elevator controller

The primary function of the elevator controller is essentially to receive and process a variety of signals from several different components of a whole elevator system. It is able to send signals in response to the ones it receives in order to operate all of the other components in the system. This exchange of signals is how the elevator controller is able to keep the elevators running smoothly on a day-to-day basis.

Here are a few of the following ways the controller interacts with the other components of the elevator system:

- Controls the speed of elevator engines in order to move elevator cabs up and down their respective shafts.

- Queues and processes elevator summons and floor requests from passengers through the signals provided to it by several buttons.

- Processes information sent to it by load sensors in order to ensure that the load of a cab never exceeds the safety limit.

- Processes information sent to it by position marker sensors in order to keep track of where the elevator cabs are at all times, as well as their speed.

- Provides feedback to passengers through the lights on some of the buttons and the floor number and direction displays in each cab.

- Can sound alarm bells that are either invoked by trapped passengers or required to warn of excess load in a cab.

- Controls the operation of the elevator doors of a cab through communication with door opening devices.

Types of elevator controllers:

There are 3 primary types of controller technology used to process the logic of the controller as follows:

1- Relay based controller (electromechanical switching)

|

| Relay based controller (electromechanical switching) |

A relay is a very dependable device consisting of an electromagnet that opens and closes contacts, routing the logic to various circuits. A simple elevator with a few stops and manual door operation can be served well by a relay controller. Relays can also be used for more complex elevators, and in fact were until the 1980's. However, the number of relays required can make it difficult to troubleshoot should there ever be a problem.

The following applications may be recommended as suitable for controllers using electromagnetic relay technology:

- Single lifts only.

- Drive speed up to 1 m/s.

- Passenger lifts in low traffic and usage situations in low-rise buildings, i.e. not more than three stories (e.g. residential buildings, very small hotels, nursing homes).

- Goods, bullion lifts in low-rise commercial buildings (e.g. offices, hotels, hospitals).

2- Solid-State Logic Technology

|

| Solid-State Logic Technology |

It includes both discreet transistors circuits and integrated circuit boards. It gives improved reliability, lower power consumption and easy fault diagnosis than electromagnetic relay technology.

The following applications are recommended as suitable for controllers using solid-state logic technology:

- Single lifts and duplex groups.

- Drive speed up to 2 m/s.

- Passenger lifts in low traffic situations in medium-rise buildings, i.e. up to 12 stories (e.g. residential buildings and small hotels).

- Goods, bullion lifts in low-rise commercial buildings (e.g. offices, hotels, hospitals).

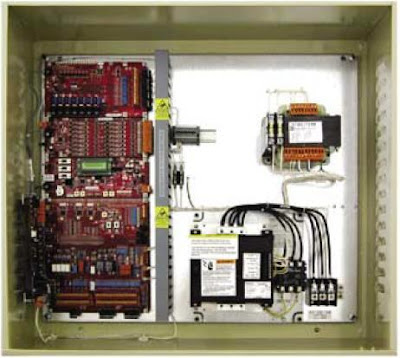

3- PLC controller (computer based technology)

|

| PLC controller (computer based technology) |

The advent of personal computers has made microprocessor technology affordable for many other fields. Elevator Concepts utilizes a special type of industrial computer called a Programmable Logic Controller PLC to control the logic of more complex jobs. They are very dependable, compact, and simple to troubleshoot.

Computer based controllers are suitable for the following:

- All lifts types.

- All drive speeds (i.e. 0.5 m/s to 10 m/s).

- Lift groups of all sizes.

Elevator Control System Sequence Diagrams

The elevator control system may be viewed either from the point of view of an individual user or as a system being acted on by many users and the following images show these different point of views.

1- From the point of view of an individual user:

2- From the point of view as a system being acted on by many users:

In the next Topic, I will continue explaining the Elevator Control System. So, please keep following.

Note: these topics about elevators in this course EE-1: Beginner's electrical design course is an introduction only for beginners to know general basic information about elevators as a type of Power loads. But in other levels of our electrical design courses, we will show and explain in detail the Elevator Loads Estimation calculations.

Note: these topics about elevators in this course EE-1: Beginner's electrical design course is an introduction only for beginners to know general basic information about elevators as a type of Power loads. But in other levels of our electrical design courses, we will show and explain in detail the Elevator Loads Estimation calculations.

No comments:

Post a Comment

thanks much for interest...